Model a Maintenance Schedule

This guide shows how to model the maintenance schedule for a generator, but the same concept applies to branches. A maintenance schedule reduces the available maximum capacity of the object between PMAXDEF and PMINDEF. The maintenance schedule is modeled by assigning a profile to the PMAX event of the object subject to maintenance. This example shows the procedure for a fuel generator (FGEN) in an electric scenario.

This example is valid for AC(O)PF scenarios.

1. Import a maintenance profile

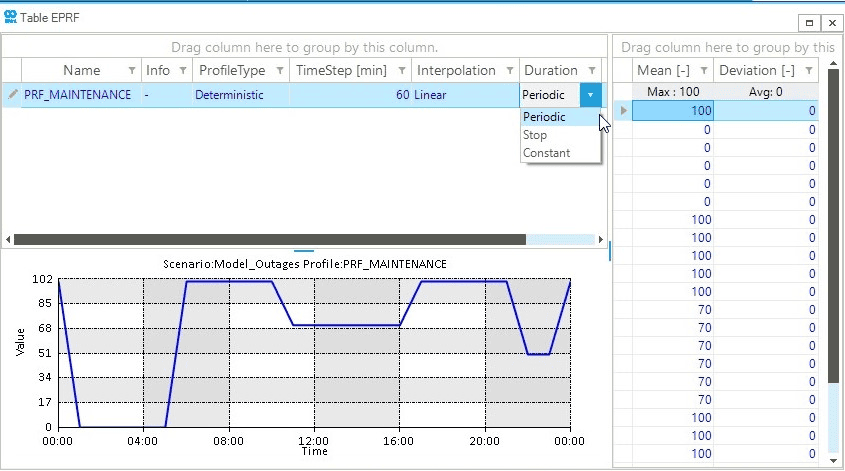

Use the Template_Profile_Import.xslx to create and import a maintenance schedule profile for the FGEN. The profile values should be between the PMAXDEF and PMINDEF properties values defined at the network level for the object. Use the Duration property of the profile to define the nature of the maintenance schedule (Periodic, Constant, etc.). Figure 1 shows an example of periodic maintenance schedule for an FGEN ranging from a maximum available capacity of 0 [MW], 50 [MW], 70 [MW] and 100 [MW].

|

While executing a simulation, an infeasibility could be created if the available capacity ( |

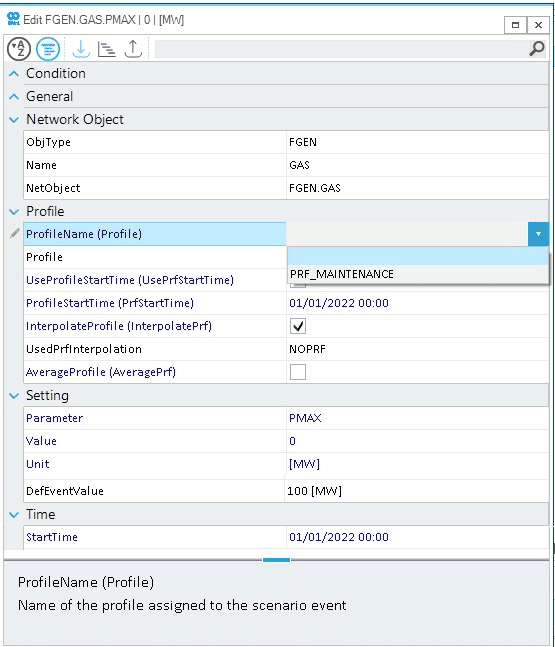

2. Create a maintenance event

The next step is to create a maintenance event and assign the profile to the event. Create a maximum active power (PMAX) event for the generator. Once the event is created, define the parameters of the events (StartTime, etc.). Finally, assign the profile to the event by selecting the profile using ▼ in the ProfileName (Profile) property, as shown in Figure 2.

|

The same principle can be used to limit the maximum capacity of a branch, or the maximum discharge of a storage object (ESTR). |